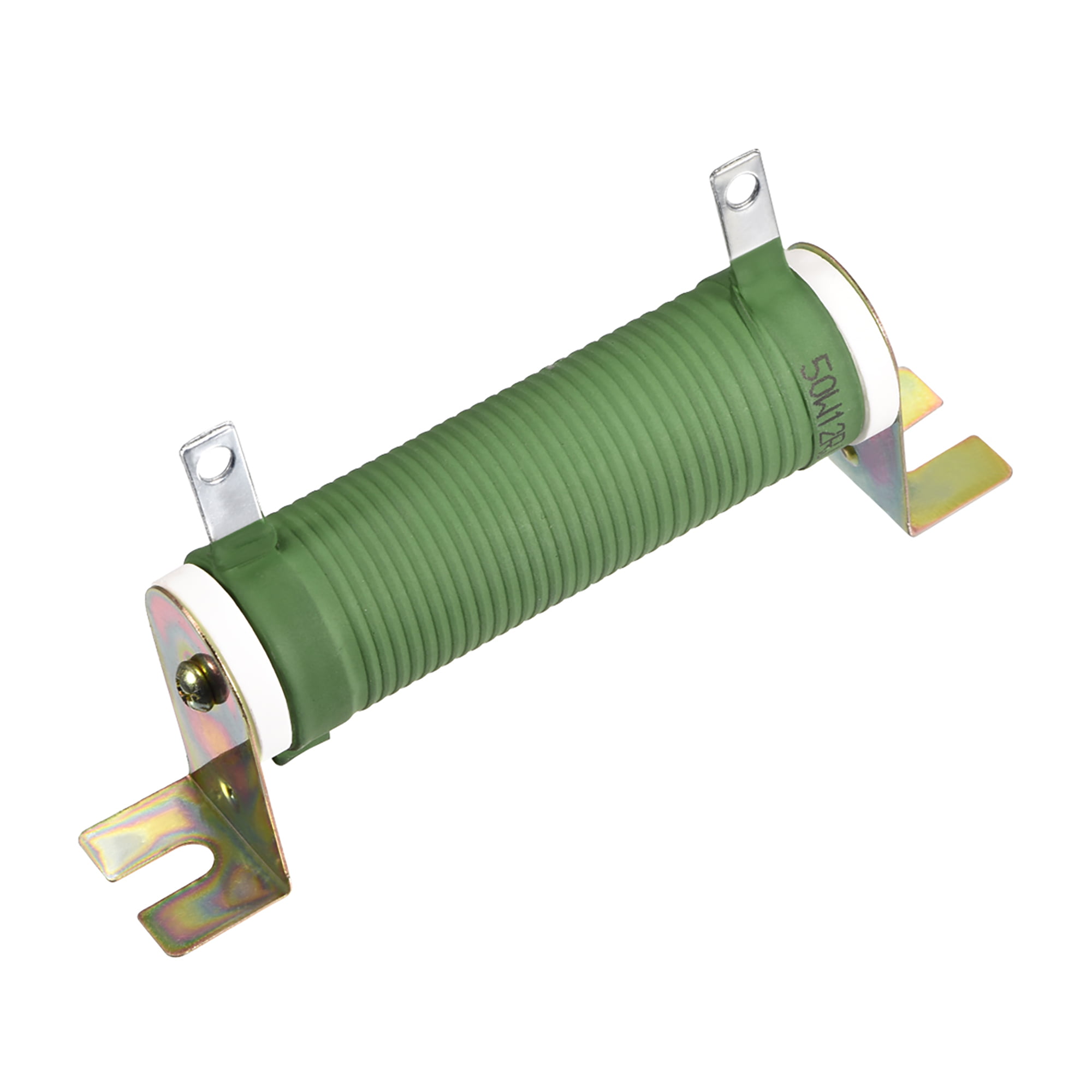

Wire Wound Resistor: From Origins to Modern Applications

The Evolution and Impact Of Wire Wound Resistor ===============================================

Since their inception, wire wound resistors have been an integral component in electronic engineering advances. Their unique characteristics and consistent performance gained them prominence in a wide array of applications. This article journeys through the origins, advancements, and adaptability of the these significant devices, uncovering their technological essence.

Looking Back at the Creation and Progress of Wire Wound Resistor

Wire wound resistor history date back to early electrical experimentation. Pioneering scientists and engineers focused on creating stable resistors that handled high-power tasks. Early models used basic metals, coiled in spirals, setting the basis for future generations.

Through the years, improvements in the material field catalyzed transformations within wire wound resistors. New discoveries in metal composites facilitated improved functionalities, providing improved thermal resistance and increased precision. Twentieth-century enhancements brought forth streamlined and efficient solutions, pushing the boundaries of effectiveness.

Leading-Edge Developments in Wire Wound Resistor Technology

Modern day advancements embody state-of-the-art construction and accuracy. Contemporary conducting substances such as nickel-chromium or copper-nickel offer more reliability while maintaining heat resistance. These advancements broaden their reach across numerous high-stakes environments.

Moreover, progressive fabrication procedures, involving computer-supported rendering, enhance design exactness. Digitalized coordination usher dynamic resistance features, enabling real-time resistance changeovers to accommodate different applications.

Using Wire Wound Resistor in Circuit Design

Practical application of wire wound resistors necessitates understanding surrounding their capabilities. While deciding on appropriate resistors, analyze attributes like resistive load, tolerance degree, and power output. Uncover the truth enable digital pioneers to adjust (electrical loads and stability, considering surrounding impacts too.

Post-installation, consistent upkeep is key to uphold component longevity. Checks might comprise temperature resilience certifications and power outputs monitored against expectations. Rectifying irregularities proactively heads off potential disruptions, keeping systems dependable in every usage scenario.

Societal Impact and Industry Dynamics

The broad effects of these resistive components transcend electrical applications. The unmatched precision they offer plays critical roles in modern society's technological fabric. Within utilities like electrical dissemination, these elements manage transmission consistency, ensuring power lines stay operational.

Medically related fields, the safeguarding of sensitive equipment relies on their function in harmonizing device conditions. Rising applications in critical areas like renewable energy, lift their critical contribution. They advance eco-friendly objectives, helping society manage resource usage wisely.

Where Wire Wound Resistor Technology is Headed

Peering into the future, these resistors will continue their journey strong. Amidst swift tech transformations, so must the performance expectations on resistors. Elevated embedding of computing utilities brings proactive resistance functions, introducing intuitive resistance collaboration.

Rising innovations, like quantum computing and AI-driven functions, seek new capabilities from wire wound resistors. Resistive designs capable of remarkable fidelity must be deployed to serve these advanced landscapes. Developers aiming for integration with these next-gen trends keep bearing the torch.

The potential of wire wound resistors endures, assured by ongoing research and professional dedication. Contributors and researchers seek to epitomize resistor refinement, producing better and more potent models, forward-pushing industry benchmarks.